Descoltech | Design

design

Customized mechanical designs

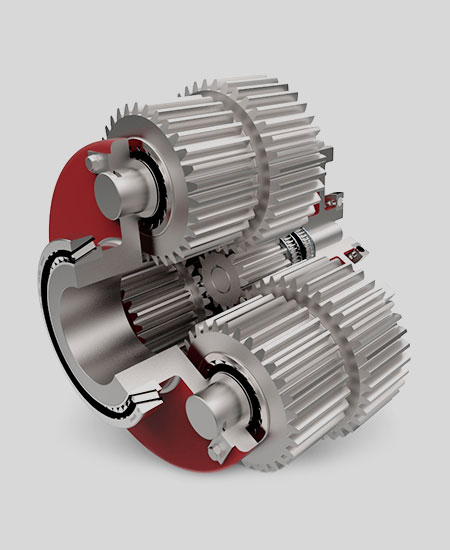

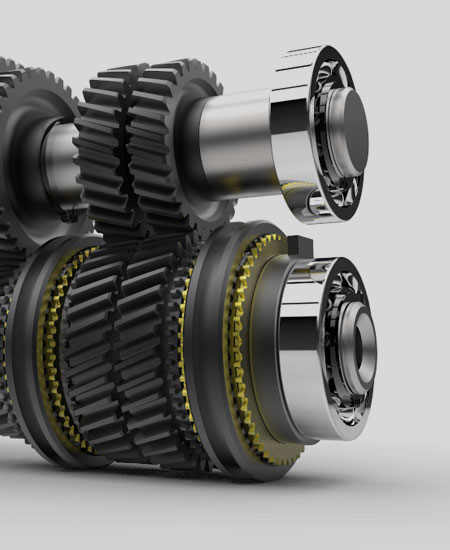

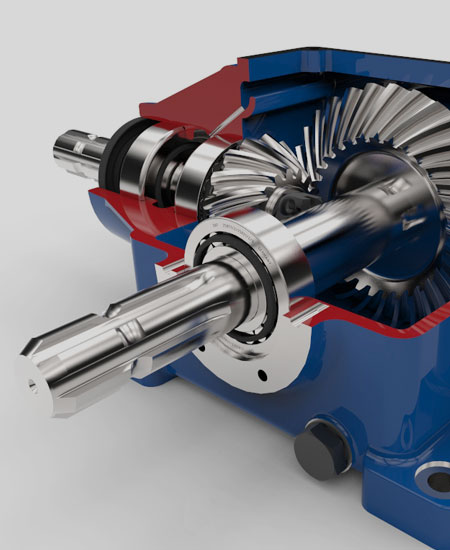

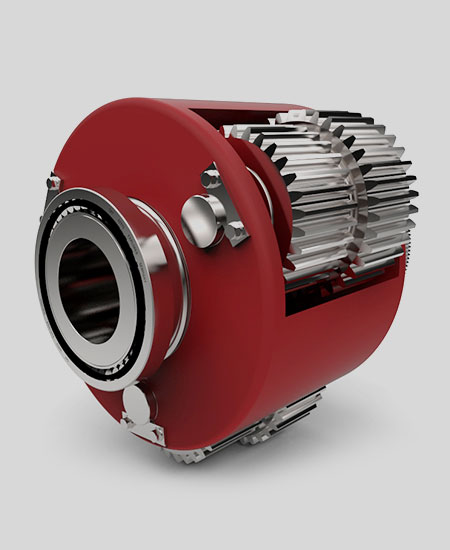

For us, simulation is an essential tool to understand or verify the behavior of a component / system before it goes into production or to optimize an existing product in terms of weight, materials, functionality. To do this, we use the most sophisticated and reliable Finite Element mechanical calculation software on the market (such as ANSYS). In addition to mechanical simulations, we carry out 3D simulations of industrial, artistic, architectural products, through dedicated graphics software.

The product presentation to the customer is essential: the support of photorealistic images and videos is an excellent visualization system.

We are able to create photorealistic images (render) and 3D animations to include them in the technical documentation.

We also assist the customer in the design and 3D drawing, carrying out machine projects and suppling the relative documentation (calculation reports, manuals …).

3D Modelling

After the concept phase of a project, which is often done with pen and paper, the detailed design begins. The tool that has caught on in the design field for years now is the three-dimensional parametric CAD. With this software it is possible to design the different components of a machine, a plant etc., then to see them interact and verify their functionality before sending into production. What is important in using these tools is not only knowing how to draw the piece in 3D, that is to arrive at the final result, but also how to get to the result. The more structured the drawing method, the generation of the features and the assemblies is, the easier and faster it will be to extract drawings, lists and other data useful for management and production. Not only that: creation of a project similar to one already carried out will take much less time.

Calculation and FEM Analysis

Finite element analysis is now an integral part of the design process.

This tool can be used for several purposes:

Preliminary calculation during design

Optimization of existing products, in terms of weight, materials, functionality

Check at the end of the design process

We can provide these FEM analyzes types:

• Linear analyzes

• Non-linear analyzes: material non-linearity (plasticization), geometric, contact ones

• Modal analysis and frequency response

• Buckling analysis

• Thermal analyzes

• Fatigue analysis

The used software (ANSYS and others) allow a precise modeling in line with reality.

Design calculations

A FEM calculation is not always necessary to solve a design problem: we also offer consultancy and support for structural, kinematic, dynamic calculations, using the common spreadsheet or other software as needed.

Experimental analyzes, non-destructive tests, measurements

When you want to validate a mathematical model (whether FEM or other), for example to be able to use it on different products of the same range, we rely on experimental analyzes to measure the real data obtained on the actual piece. These tools allow us to understand the adherence of the model to reality.

Render and Graphics

The creation of photorealistic renderings is the best tool to express the potential of a product: thanks to this powerful innovative device we are able to create extremely realistic images and videos, drawing the attention to the project and seeing it as true before its production. The purposes are:

• Realization of realistic images and videos for brochures, leaflets, websites, manuals;

• Creation of images for the product presentation to customers even before its production;

• Support for selecting the optimal materials and colors in the design phase.

All this not only in the field of industry but also, for example, of design and architecture. Thanks to the latest generation software used, high levels of performance can be achieved. Our team provides support helping company in the design phase and, subsequently, offering the possibility to receive graphic advice, such as the creation of flyers, brochures and manuals, and any other need to support product advertising.

Production development

Descoltech claims a fruitful collaboration with specialized mechanical workshops. We can offer support in the product creation, following its production and listening to the technicians suggestions. The processes that we can offer, with the help of our partners, cover the entire production cycle. The experience of our partners in the various sectors guarantees a continuous and fruitful exchange of ideas and proposals, which often lead to the optimization of costs in the implementation phase.

Column 1